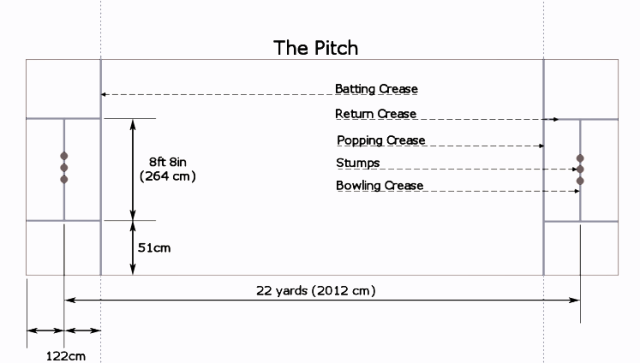

Size: Strips should be 24 meter x 3.05 meter.

Direction of pitch: Pitch length should be orientated to lie true north to south.

Slope of oval

Ideally, the oval should fall in all directions from the centre, but failing this, should have a single phase slope of 1% in any convenient direction. In the latter case, the pitch should be slightly raised to avoid problems of water draining onto or under the bulli. If the oval is on a very well drained soil no slope is required.

Slope of pitch

The slope of the pitch should not exceed 1% and it should follow the slope pattern of the oval. If the oval is centre sloped, the pitch square should also slope from the centre. The amount of fall should therefore not exceed 30mm across a 3.05m strip or 200mm along its length, being as flat as possible at the centre.

Height of pitch above outfield

The pitch square should be about 75mm above the level of the outfield to allow for surface drainage off the pitch.

Drainage

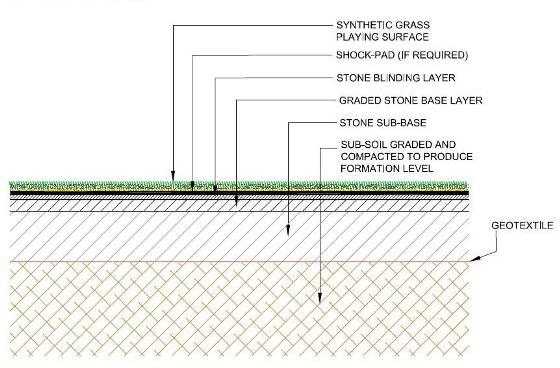

The material underlying the pitch should allow for good drainage and artificial drains might need to be installed to ensure that any water entering the sub-base will be able to drain away freely. If evapotranspiration is the only way in which water is lost from the pitch area, salts will accumulate in the bulli layer. Amongst other undesirable effects, this will promote crumbling of the pitch surface.

It is preferable to include at least one gravel layer as a sub-base, even if the underlying material allows for free drainage. An artificial drainage system is recommended if there is any indication of poor drainage. These drain pipes should be installed at a slope of 1 : 100 to quickly remove all the water from the sub-base of the pitch and the outfield.

Excavate to the desired size and depth. Decide on the number of layers to be included and their depths, and from this total subtract 75mm to allow the finished pitch to lie slightly above the outfield level. Generally, pitches for five-day matches need to be excavated to a depth of 550mm (including gravel layers) below final height; 475mm for three-day matches (again including gravel layers); and for one-day matches 400mm ( where gravel is being used) or 225mm (with no gravel layers). These depths are the minimum depth at the upper-slope edge of the pitch area, and if a layer of clay loam is to be used, the depth of this layer must be added to the above values.

Base Construction

Irrespective of the drainage capacity of the underlying material, the excavated base should be inclined in the direction of natural drainage. A ring drain should be constructed on the perimeter of the excavation to remove all excess water from the pitch area. In well drained soils a coarse gravel drain will suffice, but in poorly drained soils drainage pipes may be required and a more sophisticated system of lateral pipe-drains designed to drain the entire base.

- Excavate the trenches for the drain pipes, making sure of a fall of at least 1 : 100, and line the trenches with geotextile (e.g. Bidum). Drain pipes with a diameter of 50mm are laid on a thin layer of coarse sand and the trenches are backfilled with the same sand. CRUSHED GRANITE SHOULD NEVER BE USED for this as it forms a hard layer which severely restricts water movement.

- Coarse gravel (about 65% of the material should be between 4 and 9mm in diameter and 35% between 9 and 12mm) is then laid and its surface levelled. This layer should be about 100mm thick after having been compacted with a vibrator.

- Above this there may be an intermediate fine gravel layer approximately 100mm thick. About 90% of this gravel should be between 1 and 4mm in diameter.

The bulli

- The selected bulli should be dry and the finer it is, the better. The best mixture is one which contains 40% of aggregates less than 2mm in diameter, with about 60% less than 5mm. It must be free of stones, root material and other impurities.

For a five-day test pitch, the bulli layer must be between 250 and 300mm thick. This can be reduced to 200mm for three-day pitches and to between 150 and 200mm for one-day games.

- Where moles are likely to pose a problem, a 50mm layer of crushed glass can be laid immediately below the bulli.

In an effort to reduce the expense of buying bulli, a clay loam or sandy clay layer of 100mm is sometimes laid between the gravel and the glass, and the depth of bulli reduced to less than 100mm. This practice is certainly not recommended, but if absolutely necessary, the material should be well fertilized; especially with bonemeal and/or phosphate. The actual fertilizer need should be determined by soil analysis. Do not add compost. Compact it in the dry state with a roller to a thickness of 100mm. Score the surface after compaction to ensure proper binding between this layer and the bulli layer. Remember to mix in the fertilizer before compaction.

For one day pitches, school fields, the coarse gravel layer and the clay loam layer may not be necessary if the underlying material is well drained and the clay content less than 25%.

- Before laying the bulli, it should be air-dried and rolled on a hard surface (e.g. a car park) to ensure a degree of uniformity in particle size. This also allows an opportunity to remove stones, roots and other unwanted debris. Do not sieve the bulli.

- Add 100mm of appropriately fertilised bulli and compact in a dry condition with a roller or vibrator. Score the surface.

- The construction can then be completed by infilling to the surface with layers of bulli, each not more than 100mm thick. On each occasion the bulli must be compacted and its surface scored before any additional material is added.

It is highly recommended that the first fertilizer application, especially that of bonemeal and phosphate, be mixed with the bulli before filling. No fertilizer program can be given here, because the recommendations need to be based on soil test results.

Selection turf grass:

Warm season turf grass for cricket field: Bermuda latitude 36, Seashore paspalum, Sunday ultra dwarf etc.

Winter season turf grass for cricket field: Perennial ryegrass, Creeping bentgrass, Kentucky bluegrass, kikuyu etc.

Grass establishment

- Soak the total area before planting. All hollows and sagged areas should be filled. The grass should be planted only when the surface is dry enough to walk on without having clay stick to ones shoes.

- The grass (Skaapplaas or Bayview) can be planted in one of two ways:

(a) Grass sods are washed and torn apart to separate all the sprigs. The sprigs are then laid on the scored bulli surface and the entire sprig-covered area thoroughly wetted. A thin (10mm) layer of fine bulli is then spread carefully over the sprigs.

(b) Grass plugs can be planted in hollow-tine holes with the bulli slightly moist. Plugs should be spaced about 75mm apart.

The planted area should be watered at least once a day with a fine nozzle sprayer until there are signs of sprouting. Daily watering should continue until the grass has covered at least 75% of the area. A light dressing of dry bulli can then be spread over the pitch and levelled with a straight edge.

Post-construction maintenance

The grass should initially be allowed to grow out (to about 30mm) so that it can develop a good root system. Once it has reached full cover, its height can be reduced to 15mm.

- Once the pitch is covered and the grass is well established, the watering can be adjusted according to the weather conditions.

- The grass should be allowed at least 4 months of growth to encourage it to develop a good root system before the pitch is rolled.

- The grass should be kept to a height of about 15mm. A grass box should always be used on the mower so that cuttings can be removed.

- If the pitch surface is uneven, a light dressing of bulli can be rubbed into low lying areas. The grass must never be covered entirely and the final level should never be exceeded.

- A light hand roller can be used after each dressing to create a firm level surface.

- The grass should be cut down to 3mm only when pitch preparation starts.